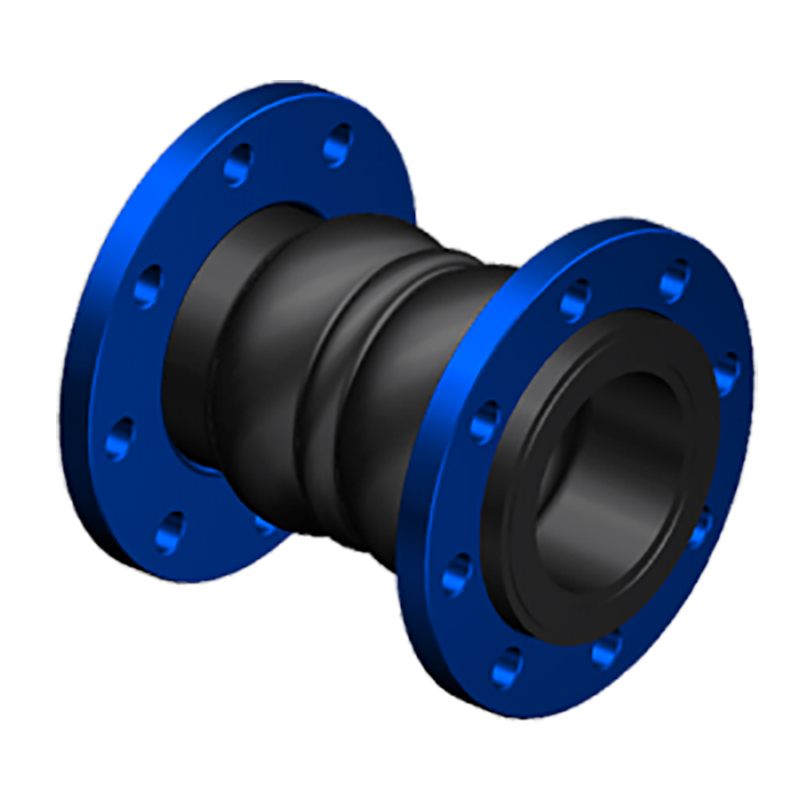

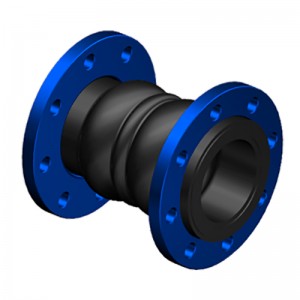

Super Purchasing for China Double Bellow Rubber Coupling (JGD-A)

We have been commitment to offer the aggressive value ,exceptional goods good quality, likewise as fast delivery for Super Purchasing for China Double Bellow Rubber Coupling (JGD-A), We sincerely welcome you arrive to visit us. Hope now we have very good cooperation inside the long term.

We have been commitment to offer the aggressive value ,exceptional goods good quality, likewise as fast delivery for China Double Bellow Rubber Coupling, Twin Sphere Rubber Expansion Joint, In order to meet our market demands, we have now paied more attention to the quality of our goods and services. Now we can meet customers’ special requirements for special designs. We persistently develop our enterprise spirit “quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

Details

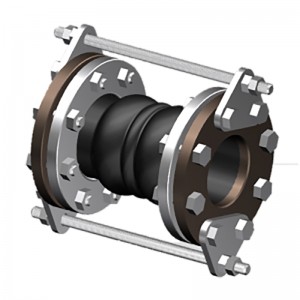

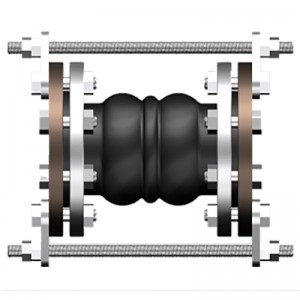

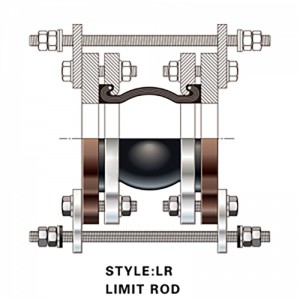

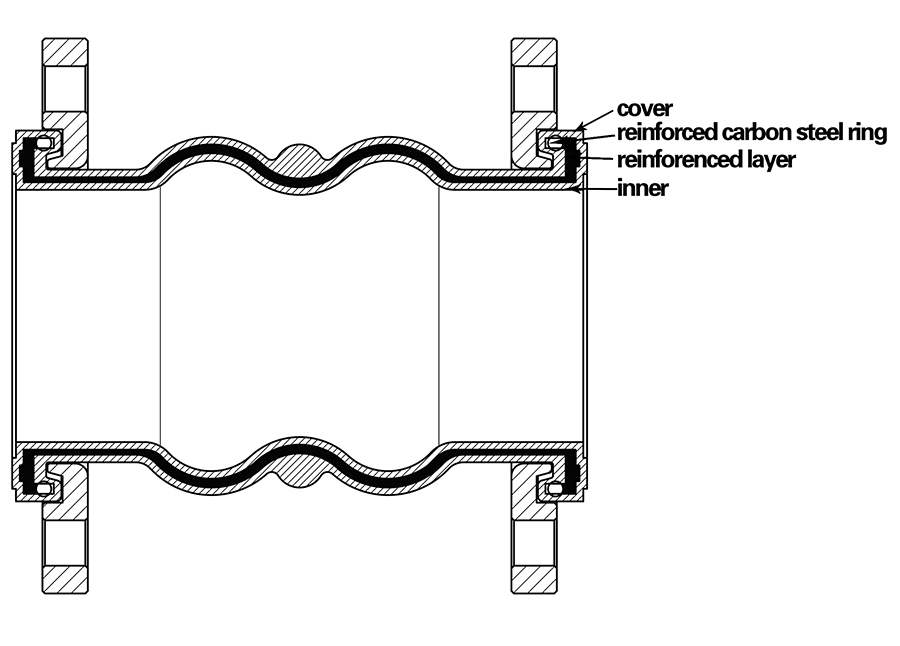

Double-arch products are used where more movement is needed. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

Double Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

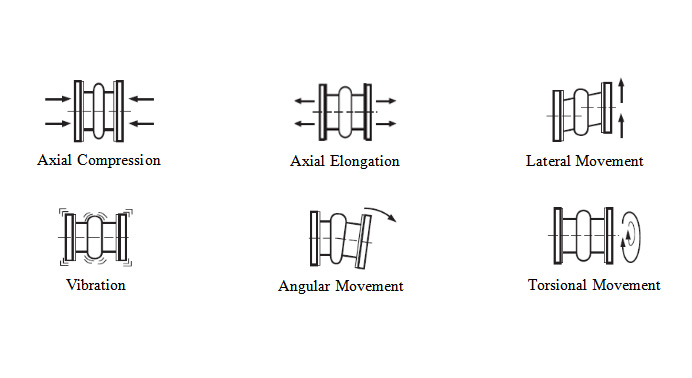

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum in. of Hg(mm hg) |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

1 1/2″ |

40 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

2″ |

50 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

2 1/2″ |

65 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

3″ |

80 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

4″ |

100 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

5″ |

125 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

6″ |

150 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

8″ |

200 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

10″ |

250 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

12″ |

300 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

14″ |

350 |

350 |

60 |

35 |

35 |

15° |

10(150) |

26(660) |

|

16″ |

400 |

350 |

60 |

35 |

35 |

15° |

7(100) |

26(660) |

|

18″ |

450 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

20″ |

500 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

24″ |

600 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

Double Arch-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

|||

|

1″ |

25 |

5″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

1 1/4″ |

32 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

1 1/2″ |

40 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

2″ |

50 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

2 1/2″ |

65 |

7″ |

2″ |

1.188″ |

±1.75″ |

43° |

225 |

26 |

|

3″ |

80 |

7″ |

2″ |

1.188″ |

±1.75″ |

38° |

225 |

26 |

|

4″ |

100 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

34° |

225 |

26 |

|

5″ |

125 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

29° |

225 |

26 |

|

6″ |

150 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

25° |

225 |

26 |

|

8″ |

200 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

19° |

225 |

26 |

|

10″ |

250 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

15° |

225 |

26 |

|

12″ |

300 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

13° |

225 |

26 |

|

14″ |

350 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

9° |

150 |

26 |

|

16″ |

400 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

8° |

150 |

26 |

|

18″ |

450 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

7° |

150 |

26 |

|

20″ |

500 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

7° |

150 |

26 |

|

24″ |

600 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

5° |

150 |

26 |

|

Double Arch-Jis Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum in. of Hg(mm hg) |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4 |

32 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

1 1/2 |

40 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

2 |

50 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

21/2 |

65 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

3 |

80 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

4 |

100 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

5 |

125 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

6 |

150 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

8 |

200 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

|

10 |

250 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

|

12 |

300 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang